In today’s automotive landscape, vehicle owners are increasingly seeking solutions that balance performance, reliability, cost-effectiveness, and environmental responsibility. One option gaining significant traction is the use of imported Japanese Domestic Market (JDM) engines. These powerplants, originally designed for vehicles in the Japanese market, offer a compelling combination of benefits that extend beyond simple mechanical reliability. This article explores the environmental and economic advantages of choosing imported JDM Mitsubishi engines and other Japanese manufacturers’ offerings as alternatives to new or domestically sourced used engines.

The Environmental Case for JDM Engines

The automotive industry’s environmental impact is substantial, with manufacturing processes accounting for a significant portion of a vehicle’s lifetime carbon footprint. Consider these environmental benefits of choosing imported JDM engines:

Resource Conservation Through Reuse

Reduced Manufacturing Demand: Every reused engine represents resources that don’t need to be extracted and processed to manufacture a new engine. This includes raw materials like aluminum, iron, copper, and various rare earth elements used in engine sensors and control systems.

Energy Savings: The energy required to manufacture a complete engine is substantial, including mining operations, material refining, casting, machining, and assembly. By extending the useful life of existing engines, this energy expenditure is avoided.

Landfill Diversion: Engine components are complex assemblies containing materials that may take centuries to decompose or that may leach harmful substances into soil and groundwater. Reusing engines keeps these materials in circulation and out of landfills.

Emissions Reduction Through Efficiency

Advanced Engineering: Many JDM engines feature sophisticated engineering focused on efficiency, particularly those designed under Japan’s strict fuel economy standards. These engines often incorporate technologies like variable valve timing, lean-burn combustion systems, and precision fuel injection that optimize performance while minimizing fuel consumption.

Lighter Weight Designs: Japanese engines frequently emphasize lightweight construction, reducing vehicle mass and improving overall fuel efficiency. This weight reduction translates to lower emissions throughout the engine’s second life.

Improved Combustion Technology: JDM engines, especially those manufactured in the last two decades, often feature advanced combustion chamber designs that maximize energy extraction from fuel while minimizing harmful emissions.

Reduced Shipping Impacts

Compact Transportation: Engines represent a concentrated form of automotive value – they’re dense packages of technology that require relatively little shipping volume compared to their utility. This efficiency in transportation contributes to a lower carbon footprint per unit of value compared to shipping entire vehicles.

Optimized Logistics: The JDM engine import industry has developed sophisticated logistics networks that maximize shipping efficiency, often using containerized transport that minimizes the environmental impact per engine moved.

The Economic Advantages of JDM Engines

Beyond environmental benefits, imported JDM engines offer substantial economic advantages to vehicle owners and the broader automotive ecosystem:

Cost-Effectiveness for Vehicle Owners

Lower Initial Investment: JDM engines typically cost significantly less than new OEM replacements while offering comparable or superior quality. This price advantage makes engine replacement a viable option for vehicles that might otherwise be scrapped due to engine failure.

Reduced Labor Costs: In many cases, JDM engines come with ancillary components already attached, potentially reducing installation time and associated labor costs compared to rebuilding an existing engine.

Extended Vehicle Lifespan: By making quality engine replacements economically feasible, JDM engines help extend the useful life of vehicles, delaying the substantial financial outlay required for vehicle replacement.

Performance Upgrades at Minimal Premium: For enthusiasts, JDM engines often represent an opportunity to upgrade performance characteristics without the premium cost typically associated with performance modifications.

Broader Economic Benefits

Specialized Business Development: The JDM engine market has spawned numerous specialized businesses focused on importation, testing, reconditioning, and installation. These enterprises create jobs and contribute to local economies.

Skills Development: Working with JDM engines requires specialized knowledge, creating opportunities for mechanics and technicians to develop valuable expertise that enhances their economic prospects.

Aftermarket Support Economy: The popularity of JDM engines drives demand for compatible components, specialized tools, and technical knowledge, supporting a robust aftermarket economy.

Quality and Reliability Factors

The economic and environmental benefits of JDM engines are closely tied to their renowned quality and reliability:

Engineering Excellence

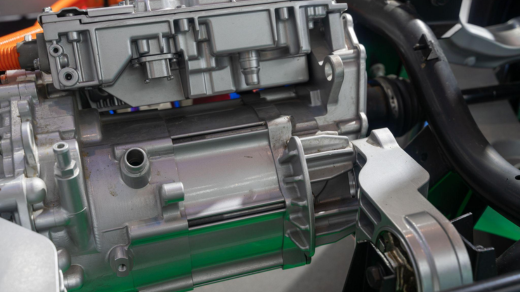

Precision Manufacturing: Japanese manufacturers are known for maintaining extremely tight tolerances in their manufacturing processes, resulting in engines with excellent internal balance and reduced wear characteristics.

Material Quality: Japanese engines often utilize high-grade materials for critical components, contributing to their longevity and reliability under stress.

Rigorous Testing: Before leaving the factory, Japanese engines undergo extensive testing to ensure they meet stringent performance and durability standards.

The JDM Advantage

Lower Lifetime Stress: Due to Japan’s geographic characteristics and driving patterns, many JDM engines experience less lifetime stress than their counterparts in other markets. Japanese roads generally have lower speed limits, and the country’s excellent public transportation infrastructure means many vehicles are driven less frequently.

Maintenance Culture: Japan has a strong culture of preventive maintenance, meaning engines sourced from the Japanese market are more likely to have received regular servicing throughout their initial lifecycle.

Early Retirement: Japan’s vehicle taxation system and inspection requirements make it economically disadvantageous to keep older vehicles on the road. Consequently, many engines are exported while still having substantial service life remaining.

Practical Considerations for Potential Buyers

To maximize the environmental and economic benefits of choosing a JDM engine, consider these practical factors:

Supplier Selection

Reputation and Transparency: Work with suppliers who provide detailed information about their sourcing practices, testing procedures, and quality control measures.

Warranty Coverage: Look for suppliers offering meaningful warranty protection, which not only provides peace of mind but also indicates the supplier’s confidence in their product.

Documentation: Reputable suppliers provide comprehensive documentation of the engine’s history, condition, and testing results.

Installation Considerations

Professional Installation: Having your JDM engine installed by experienced professionals helps ensure proper integration with your vehicle’s systems, maximizing reliability and performance.

Emissions Compliance: Ensure any engine swap complies with local emissions regulations to avoid legal complications and minimize environmental impact.

Proper Maintenance: Following manufacturer-recommended maintenance schedules is essential for realizing the full economic and environmental benefits of your JDM engine.

Conclusion

The choice to install an imported JDM engine represents more than just a mechanical decision—it’s an option with significant environmental and economic implications. By extending the useful life of quality engineered components, vehicle owners can reduce their environmental footprint while enjoying the economic benefits of cost-effective, reliable performance.

As automotive technology continues to evolve, the market for quality used components like JDM engines provides an important bridge between traditional internal combustion technology and future propulsion systems. This market allows vehicle owners to make environmentally responsible choices while managing costs effectively, demonstrating that economic and environmental considerations can align harmoniously in the automotive realm.